Overview

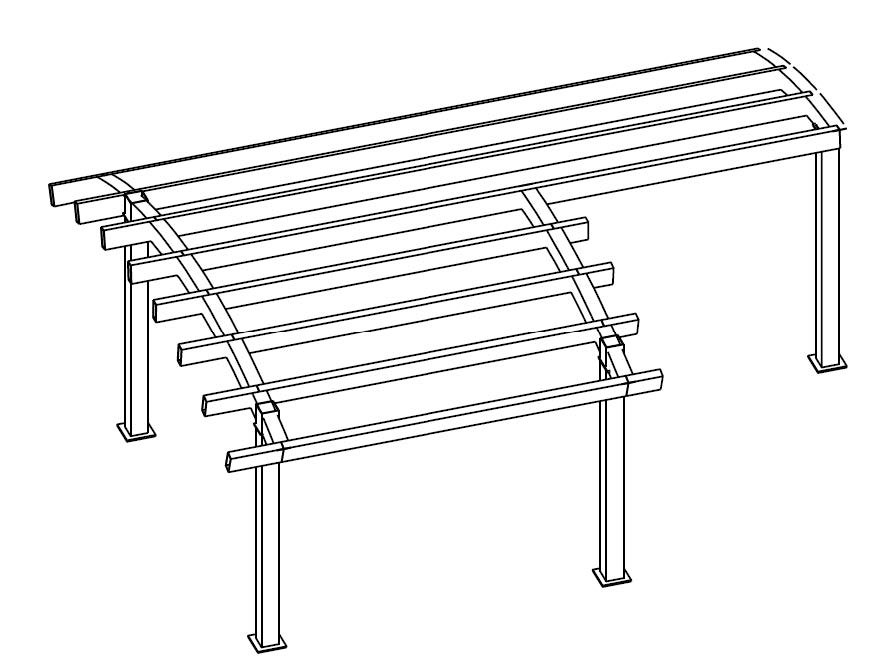

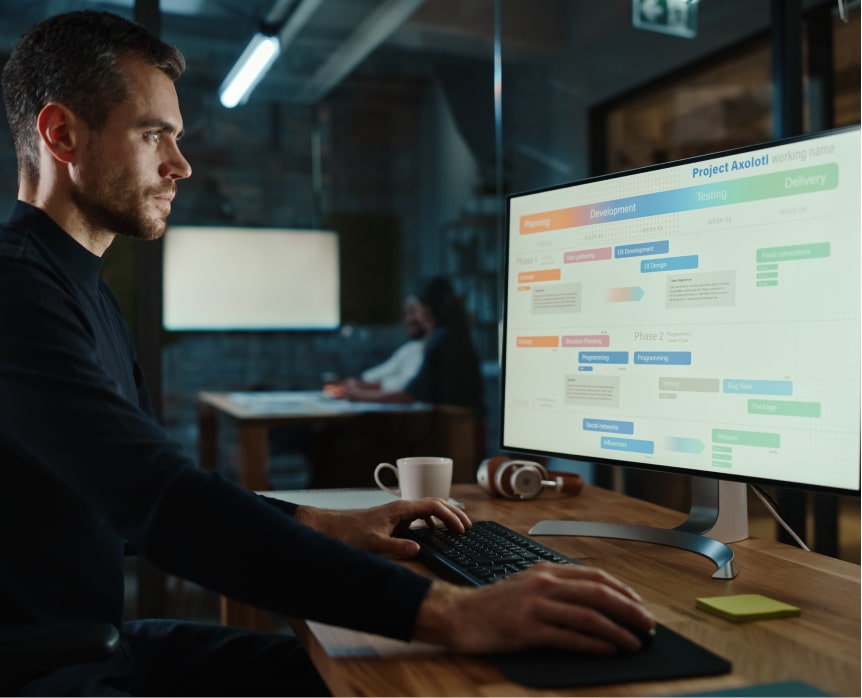

Steel Detailing Project management tool is essential for any steel fabricator in the construction industry. There is no better way to get an instant overview of the status of every stage of the project at any time.

A good steel detailing project tracking and management tool increases efficiency while saving time throughout the entire process. Such project handling software enables users to manage all projects simultaneously on a single platform.

FabTrack by Liberty Innovations

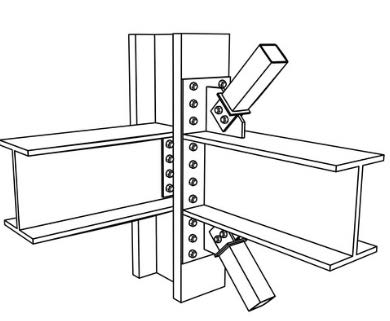

Structural steel detailing is critical and demands a high level of accuracy. Liberty Innovations is here to make this process easier.

FabTrack is a steel detailing management software application specially designed to automate and streamline the entire steel detailing project management process from beginning to end. Even the most complex project architecture gets broken down and laid out in an easy-to-use-and-understand manner in this user-friendly application.

FabTrack is a centralized platform covering all aspects of the steel detailing project, from bidding to sharing drawings to completion. It enables users to provide specification inputs to change orders and manage RFIs. The inbuilt messaging feature makes communication between all team members and partners straightforward.

What Makes FabTrack

the Best Project Handling Software?

FabTrack brings much-needed order to the steel detailing project handling process and paves the way for better management of all critical components. Check out some of the many reasons our users love using FabTrack when they need to execute steel detailing project of any size project.

Real-Time Data Management

FabTrack provides real-time data management and notifications and facilitates storage for both large and small projects. All the entries on the platform are made automatically in real-time. Using FabTrack, the cross-process between the steel fabricator and the steel detailer runs flawlessly.

Intuitive Experience

FabTrack's simple user interface is easy to use and ensures an excellent experience for all users. New users can get started with FabTrack with very little training or prior project handling software experience. Core users can easily keep track of each project and distinguish between multiple projects at once.

Enhanced Communication

Within the FabTrack platform, the admin creates a project and subsequently brings in integral roles for the job, including the fabricator and the detailer. The built-in chat box feature lets all parties communicate about a project's status and immediate needs. FabTrack also provides a separate channel for issuing Change Orders which ensures that required changes are approved or rejected without any delay.

Request for Information (RFI) Tool

FabTrack eliminates the need to go through the time-consuming process of shuffling through endless email threads to find a specific piece of information from a particular steel detailer or fabricator. With our RFI tool, both fabricators and detailers can raise requests at any time, and the other end immediately gets a notification on the software. This easy process allows both parties to take immediate action on the request. FabTrack also enables users to set the priority level of each request so that the team can take appropriate and timely measures.

Advantages

Quicker Fabrication

FabTrack provides users with a comprehensive designated tool for communicating with steel detailers and fabricators to make your life easier. Forget about exchanging thousands of emails to get one job done! You can now use this revolutionary tool to create the project, set project timelines, and work along with your detailer utilizing the convenience of a centralized platform.

Accurate Results

Mistakes often hinder and delay important project operations. With FabTrack's project-oriented Change Order tool, users can make changes in real-time while the detailer is still working on the project. Due to this, all the shop drawings and erection drawings get completed on time and with unparalleled accuracy.

Reduction in Overall Costs of Fabrication

The RFI feature of FabTrack gives it a competitive edge over similar project handling software applications. It enables the fabricator to proceed with correct and approved drawings, thus avoiding expensive remediation of jobs. The RFI tool helps fabricators and detailers seek information that makes their jobs more manageable, and the platform always prioritizes RFIs. FabTrack enables you to reduce labor and material costs due to more efficient project communication and execution.

Increased Profits

Small and large fabrication shops alike can capitalize on the smart integration of steel detailing and fabricating processes using FabTrack. Our happy customers witness a surge in their profits due to more streamlined procedures. FabTrack is easy to use, and it helps enhance the quality of work. Moreover, using FabTrack saves valuable company resources while increasing the speed of production and delivery.

Applications

FabTrack assists the user from the time they bid on a contract to the final quality check of the finished product. It automates inventory tracking, project scheduling, cost calculation, quoting, and bid proposal generation.

How will FabTrack help with your project workflow? With one simple tool, your team can take advantage of these exceptional benefits.

Save basic details of all the contractors, subcontractors, and steel detailers you work with for repeated use.

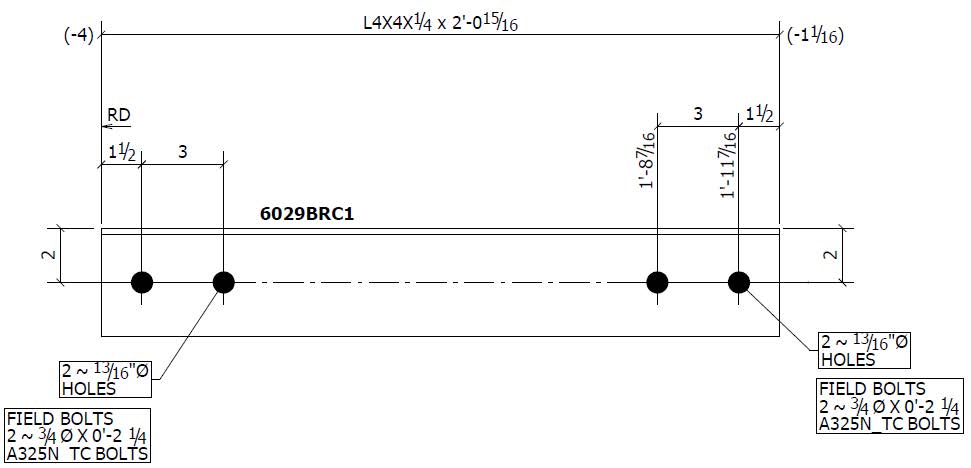

Keep track of all the drawings, including contractor, subcontractor, erection, and fabrication drawings.

Stay up to date with the status of the completion of projects and project segments.

Manage precise traceability of materials through Change Orders and RFIs — FabTrack makes it easy to access the entire history on a single platform.

Get real-time progress reports and project completion notifications.

Keep communication channels of projects with different detailers separate for ease of reference.

Never miss out on a Change Order update or RFI with the app's built-in notifications tool.

Eliminate the need to sort through countless emails and paperwork to get a single project completed.

FabTrack is Now Available

on Your Smartphone!

Liberty Innovations worked to bring FabTrack to your fingertips. Now, you can access critical notifications for all your projects using the FabTrack mobile app.

The mobile app interface is minimal and straightforward so that you can handle your projects with ease. Do not let the simplicity of this handy app fool you! It has all the features you need to access your projects and RFIs and manage your communications through the chat option.

Training and Support

We offer an orientation and training demo for your entire team. Our skilled instructors will walk your employees through project management from conception to execution. Plus, we are always available to answer your pressing questions.

Stop stressing over fabrication!

Get in touch with us today to get a free demo of the incredible FabTrack software tool for efficient steel detailing project management.

Learn More & Download trial version

Get In Touch

Basic Info

Message

Submit

Liberty Steel © 2022 Developed by Pixelfly Innovations